Multi-Stage Centrifugal

- AMT - Calpeda

- 1 1/4" - 6" Discharge

- 2600 GPM

- 2600' TDH

- Constant Pressure Booster Pak Systems Available

Multi-Stage Centrifugal Pumps from AMT & Calpeda

Pump Solutions distributes multi-stage centrifugal pumps from a number of manufacturers, including AMT and Calpeda. If you have questions or would like to order a multi-stage centrifugal pump, contact our pump providers in Wisconsin today.

CONTACT US TODAY For details & pricing!

Applications Ideal for Multi-Stage Centrifugal Pumps

For applications that require a high output or just high pressure in general, a multi-stage centrifugal pump might be the right pump for your needs.

To design a centrifugal pump with a single impeller developing a differential pressure of more than 150 PSID between the suction and the discharge is difficult and costly. A more economical approach to gaining the same results is to go with a multi-stage centrifugal pump.

A multi-stage centrifugal pump is a centrifugal pump that contains two or more impellers: either mounted on the same shaft or different shafts.

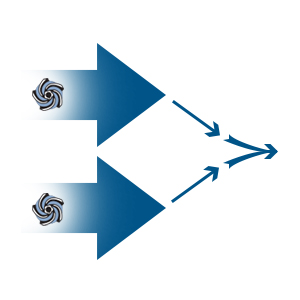

- To achieve higher pressures at outlet, the impellers may be connected in series.

- For high output, the impellers may be connected parallel.

Here’s a visual example of series and parallel impeller set-up:

Diagram of Impellers in Series |

Diagram of Impellers in Parallel |

|

|

Note: when connected in series, the impellers don’t have to be in a square shape, they just have to be connected.

Pros and Cons of Multi-Stage Centrifugal Pumps

| Pros | Cons |

| Higher efficiency | Many parts inside the casing to maintain and service |

| Higher output power (PSID) | Parts inside the casing are difficult to get to |

| Various and customizable build | Expensive initially and to maintain |

Centrifugal Pump Basics

- Centrifugal pumps consist of one or more rotating impellers inside a stationary volute – the casing

- The liquid enters the pump through the suction inlet into the eye of the impeller

- The speed of the rotating impeller(s) forces the substance out through the discharge nozzle

- The liquid enters the inlet of the centrifugal pump under atmospheric pressure, and flows into the eye of the impeller

- Using centrifugal force, the substance moves away from the impeller eye and out along the impeller vanes where the substance is forced against the inside walls of the volute and out through the discharge of the pump

- Due to the reduction of pressure occurring at pump inlet and impeller eye, substance is drawn into the pump in continuous flow through suction

To make an educated decision on your pump needs, contact our centrifugal pump specialists at Pump Solutions #1 Corp!

To fully use this site, please enable Javascript

SHOP PRODUCTS

SHOP PRODUCTS